How xylanase can enhance swine productivity

By Dr. Ajay Awati, Director of Enzymes, EW Nutrition

The use of by-products and high-fiber ingredients in feed formulations has increased in swine operations. Driven by both economic and sustainability goals, this shift has emphasized the importance of understanding the role of dietary fibers and carbohydrases in swine nutrition and health (Petry & Patience, 2020). These feeds rich in fiber are generally considered to have low nutritional value due to the lower digestive energy or amino acid levels when compared to concentrated feeds with high starch or proteins (Woyengo et al., 2014).

Dietary fiber is vital in pig nutrition, necessitating a baseline inclusion to support regular digestive tract functions (Wenk, 2001). Incorporating fiber into the diets of monogastric animals raises concerns due to its correlation with reduced nutrient utilization and diminished net energy levels (Noblet; Le Goof, 2001). High-fiber diets can present challenges for inclusion in monogastric animals’ feeds, especially young animals, due to their bulky nature and restricted ability to ferment fiber, impacting nutrient uptake based on fiber type, the age of the pig, and diet composition (Bach Knudsen et al., 2012).

Moreover, the apparent ileal digestibility (AID) of nutrients is adversely affected by dietary fiber, attributed to the small intestine’s deficiency in endogenous enzymes necessary for breaking down these bonds (Bach Knudsen et al., 2012).

This article aims to demonstrate how enzymatic degradation of arabinoxylans, particularly through xylanase enzymes, can mitigate anti-nutritional effects and enhance the nutritional value of high-fiber swine diets, thereby improving animal health and performance.

Into the World of Arabinoxylans

In plants classified as monocotyledonous, such as cereals, the main non-starch polysaccharides (NSP’s) components of the cell wall are arabinoxylans, cellulose and β-glucan (Bach Knudsen, 1997). Arabinoxylans represent a complex group of dietary fibers with significant implications for swine nutrition and health. Their structural heterogeneity can influence physicochemical properties, biological activities, and affect pigs’ gut microbiota and immune system. Present in both soluble and insoluble forms, it consists of a backbone of xylose residues with arabinose side chains, playing a crucial role in the nutritional dynamics within swine diets (Mudgil & Barak, 2013).

The fermentability of corn-based dietary fiber is limited by its insoluble fraction and complex branched structure; impacting the digesta transit rate and reducing the digestibility of nutrients (Gutierrez et al., 2013). Supplementing exogenous carbohydrases offers a viable approach to enhance the utilization of fiber that is otherwise difficult to ferment, potentially amplifying its positive effects.

Xylanase’s Impact on Fiber and Gut Health

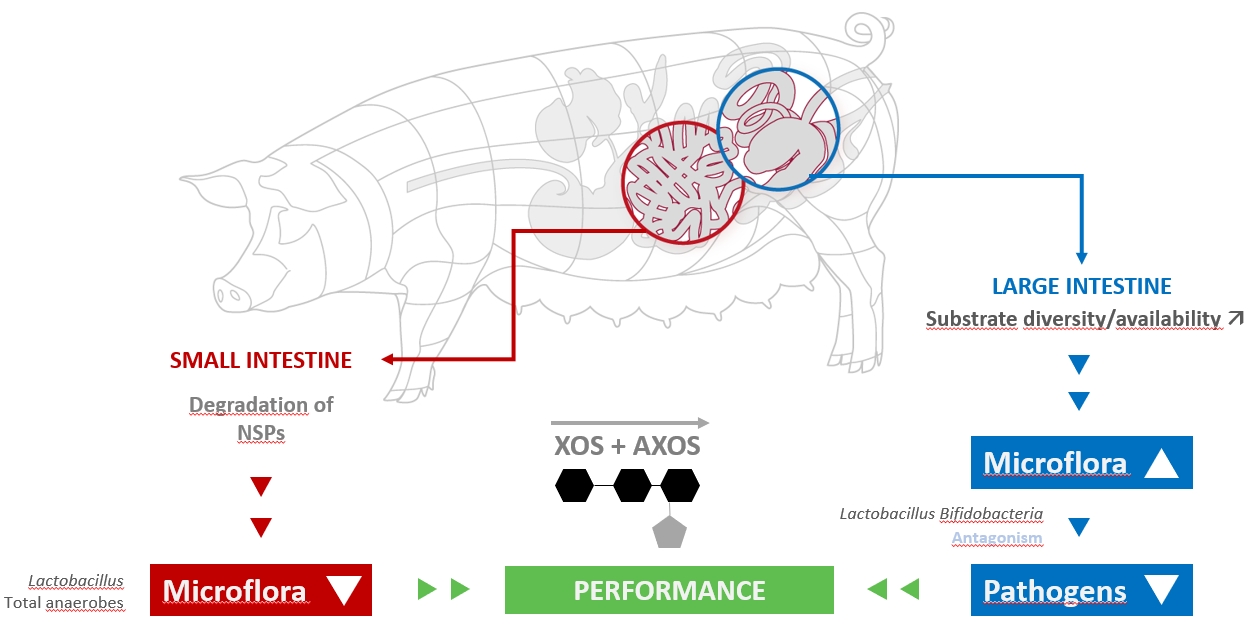

Non-digestible carbohydrates may be fermented by microbial populations along the gastrointestinal tract to synthesize short-chain fatty acids that may be absorbed and metabolized by the pig. Such indigestible carbohydrates consist of specific disaccharides, oligosaccharides, resistant starches, and non-starch polysaccharides. The presence and composition of these indigestible carbohydrates in pig diets vary based on the types of feed ingredients incorporated into their meals (Navarro et al., 2019). Xylanase works on the hydrolysis of the arabinoxylan fraction of NSPs. The NSPs present in the walls of plant cells encapsulate nutrients, making them unavailable for the action of the animal’s own digestive enzymes. Moreover, NSPs exhibit a high affinity for water within the gastrointestinal lumen, leading to elevated digesta viscosity. This increased viscosity reduces gastrointestinal motility, facilitating an environment conducive to the proliferation of pathogenic microflora (Choct, 1998). The advantageous outcomes of enzyme supplementation arise from the enzymatic disruption of intact cellular membranes, leading to the release of sequestered nutrients, or are a consequence of modifying the physicochemical properties of non-starch polysaccharides, due to changes in viscosity and water-holding capacity and/or changes in the composition and content of bacteria in the intestine (Bedford, M. R., & Classen, 1992).

Arabinoxylans in Cereal Grains and Their By-products

Factors such as genetics, climate, maturity stage, fertilizer use, and post-harvest storage time influence the proportion of total cell wall polysaccharides in cereal grains. These factors vary across production systems and countries, depending on the availability of feed resources (Paloheimo et al., 2010).

Cereal grains and their by-products, including wheat bran, corn distillers dried grains with solubles (DDGS), and rice husks, serve as significant sources of arabinoxylans. Their incorporation into swine diets is growing due to economic advantages.

The ethanol industry’s growth has increased the availability of distillery by-products. Brazil alone generates an estimated 366 million tons of DDGS annually (USDA, 2017). Among these by-products, distiller-dried grains are prevalent, especially in the U.S. pork industry as feed ingredients.

Corn, wheat, and barley, as staple ingredients in swine feed, exhibit significant variations in their NSP and arabinoxylans content. In grain form, corn contains 4.7% AX with a soluble component of 0.5%, while wheat has a higher arabinoxylans content at 7.3% with 1.8% being soluble. Barley stands out with the highest arabinoxylans content at 8.4%, of which 1.2% is soluble, reflecting its rich fiber composition. The processing into flour results in a reduction of arabinoxylans content across all three cereals, highlighting the impact of processing on dietary fiber availability (Knudsen, 2014).

Rice distillers’ by-product is recognized as a valuable protein source, boasting high crude protein levels. Nonetheless, its high fiber content can restrict usage (Huang et al., 2017). Wheat bran is particularly rich in arabinoxylans, enhancing its dietary fiber content. DDGS also contain significant amounts of both soluble and insoluble arabinoxylans, resulting from the corn kernel’s residual non-starch polysaccharides (Agyekum & Nyachoti, 2017).

It is essential to understand the specific levels of arabinoxylans in these components to create balanced diets that optimize nutritional benefits while minimizing potential anti-nutritional effects.

Addressing Arabinoxylan Degradation

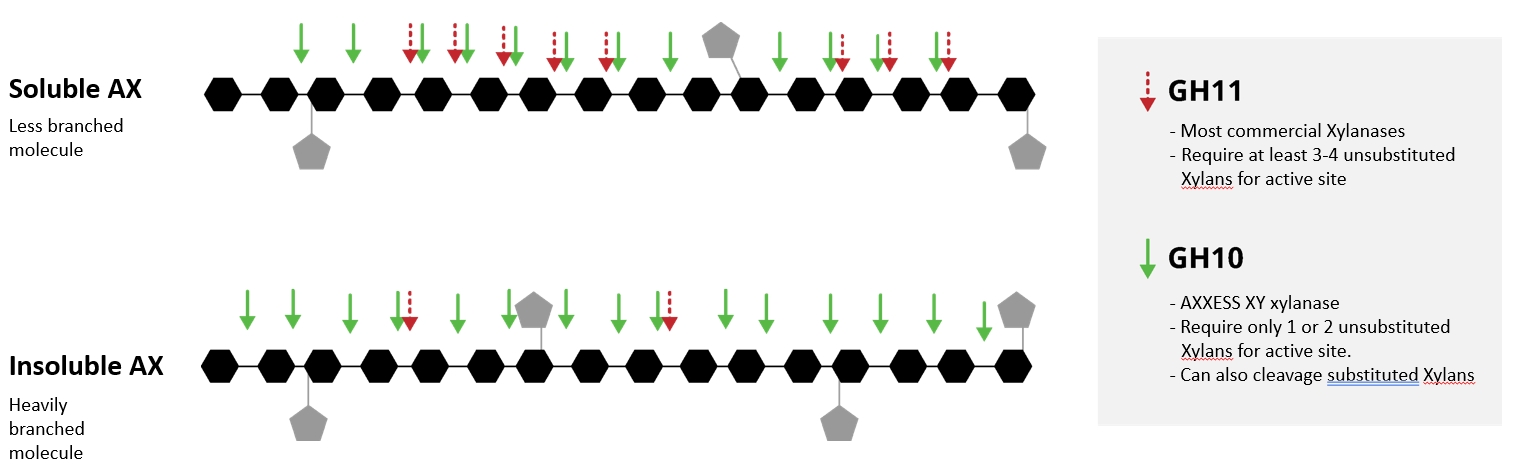

Xylanases target specific substrates, necessitating the presence of arabinoxylans for their effective action. The complex structure of arabinoxylans makes them resistant to degradation by the swine’s endogenous enzymes, presenting a dual challenge: how to harness the beneficial effects of soluble arabinoxylans while mitigating the negative impacts of their insoluble counterparts.

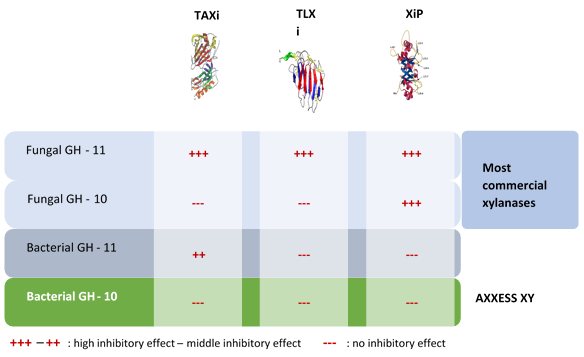

These enzymes specifically cleave the 1,4-β-D-xylosidic bonds in arabinoxylans, randomly targeting xylose linkages within the xylan structure. Each enzyme type has a unique pattern of degradation (Collins et al., 2005) and GH 10 xylanases specialize in breaking down arabinoxylans with high arabinose substitution into smaller oligosaccharides. These oligosaccharides are valuable for fermentation, serving as energy sources or prebiotics.

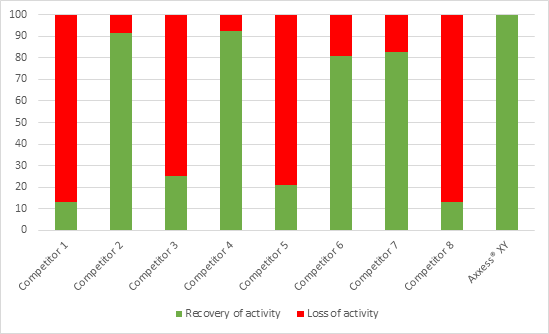

Also, this group of enzymes action not only reduces gut viscosity but can lead to enhanced feed efficiency, growth performance, and overall health of swine by improving the digestibility of fibrous components in feed (Lærke et al., 2015). GH 10 xylanases often have optimal activity at pH levels found in the animal gut, and their thermal stability ensures they retain activity under feed processing temperatures. Lei et al. (2016) highlighted the efficacy of xylanase in improving nutrient digestibility and overall feed efficiency. By targeting the arabinoxylans present in swine diets, xylanase enzymes facilitate a more efficient conversion of feed into energy, contributing to improved growth rates and performance metrics.

As detailed by Tiwari, Singh, & Jha (2019), arabinoxylans undergo fermentation in the gut, leading to the production of short-chain fatty acids (SCFAs) that beneficially alter the gut microbial ecology. The application of GH 10 xylanases has been highlighted for its potential to significantly enhance the degradation of arabinoxylans, thereby improving the fermentation process and increasing the yield of SCFAs. This enzymatic breakdown facilitates more efficient nutrient absorption and overall better gastrointestinal health, directly influencing swine growth and performance positively.

A study reveals that xylanase supplementation significantly reduces mortality rates in pigs in a dose-dependent manner. With mortality rates dropping from 4.16% in the control group to as low as 2.25% with the highest xylanase dosage, the results highlight xylanase’s potential to improve gut health and increase survival rates. This suggests a promising approach for boosting pig well-being and reducing the reliance on enteric antibiotics, marking a significant stride in sustainable animal nutrition practices.(Zier-Rush et al., 2016).

The research conducted by Petry et al. (2020) demonstrated that xylanase increased the digestibility of non-starch polysaccharides, particularly arabinoxylan, in diets high in insoluble corn fiber. This improvement in nutrient absorption highlights xylanase’s role in optimizing the use of high-fiber ingredients in swine diets, thereby enhancing animal health and performance. Due to its cost-effectiveness and nutrient profile, xylanase supplementation enhances the nutritional value of DDG in swine diets.

The strategic implementation of xylanase in swine diets represents a promising approach to the challenges posed by high-fiber feed ingredients. By improving the digestibility of arabinoxylans and other complex carbohydrates, xylanase supplementation can mitigate the anti-nutritional effects of insoluble fibers, enhance feed efficiency, and support optimal growth and health outcomes in swine.

Enhancing Swine Productivity with Enzyme Solutions

With the growing incorporation of co-products in swine feed, there arises a crucial need to transform the high fiber content into a beneficial asset for the animals. The strategic incorporation of enzyme solutions, particularly xylanase enzymes, into swine feed formulations emerges as a scientifically supported approach to significantly enhance the digestibility of high-fiber diets. This method effectively addresses the nutritional intricacies posed by arabinoxylans, facilitating improved feed utilization. Moreover, the action of xylanase enzymes extends beyond enhancement of nutrient absorption; it plays a pivotal role in promoting the health and performance of swine. Such targeted nutritional strategies are vital in the context of swine production systems, highlighting the necessity of integrating these enzymatic solutions to achieve optimal animal health, growth, and productivity.

References:

- Agyekum, K. A., & Nyachoti, C. M. (2017). Nutritional and metabolic consequences of feeding high-fiber diets to swine: A review. Engineering, 3(5), 716-725. https://doi.org/10.1016/J.ENG.2017.03.010

- Bach Knudsen, K. E. (1997). Carbohydrate and lignin contents of plant materials used in animal feeding. Animal Feed Science and Technology, 67, 319-338.

- Bach Knudsen, K. E., Hedemann, M. S., & Laerke, H. N. (2012). The role of carbohydrates in intestinal health of pigs. Animal Feed Science and Technology, 173, 41–53.

- Bedford, M. R., & Classen, H. L. (1992). Reduction of intestinal viscosity through manipulation of dietary rye and pentosanase concentration is effected through changes in the carbohydrate composition of the intestinal aqueous phase and results in improved growth rate and food conversion efficiency of broiler chicks. The Journal of Nutrition, 122, 560-569.

- Choct, M. (1998). The effect of different xylanases on carbohydrate digestion and viscosity along the intestinal tract in broilers. Australian Poultry Science Symposium, 10.

- Collins, T., Gerday, C., & Feller, G. (2005). Xylanases, xylanase families and extremophilic xylanases. FEMS Microbiology Reviews, 29(1), 3–23. https://doi.org/10.1016/j.femsre.2004.06.005

- Gutierrez, N. A., Kerr, B. J., & Patience, J. F. (2013). Effect of insoluble-low fermentable fiber from corn-ethanol distillation origin on energy, fiber, and amino acid digestibility, hindgut degradability of fiber, and growth performance of pigs. Journal of Animal Science, 91, 5314–5325. https://doi.org/10.2527/jas.2013-6328

- Huang, Y. F., Gao, X. L., Nan, Z. B., & Zhang, Z. X. (2017). Potential value of the common vetch (Vicia sativa L.) as an animal feedstuff: A review. Journal of Animal Physiology and Animal Nutrition, 101, 807-823. https://doi.org/10.1111/jpn.12617

- Lærke, H. N., Arent, S., Dalsgaard, S., & Bach Knudsen, K. E. (2015). Effect of xylanases on ileal viscosity, intestinal fiber modification, and apparent ileal fiber and nutrient digestibility of rye and wheat in growing pigs. Journal of Animal Science, 93(9), 4323-4335.

- Lei, Z., Shao, Y., Yin, X., Yin, D., Guo, Y., & Yuan, J. (2016). Combination of xylanase and debranching enzymes specific to wheat arabinoxylan improve the growth performance and gut health of broilers. Journal of Agricultural and Food Chemistry, 64(24), 4932-4942.

- Mudgil, D., & Barak, S. (2013). Composition, properties and health benefits of indigestible carbohydrate polymers as dietary fiber: a review. International Journal of Biological Macromolecules, 61, 1-6. https://doi.org/10.1016/j.ijbiomac.2013.06.044

- Navarro, D. M. D. L., Abelilla, J. J., & Stein, H. H. (2019). Structures and characteristics of carbohydrates in diets fed to pigs: a review. Journal of Animal Science and Biotechnology, 10, 39. https://doi.org/10.1186/s40104-019-0345-6

- Noblet, J., & Le Goff, G. I. (2001). Effect of dietary fibre on the energy value of feeds for pigs. Animal Feed Science and Technology, 90, 35-52.

- Paloheimo, M., Piironen, J., & Vehmaanperä, J. (2010). Xylanases and cellulases as feed additives. In M. Bedford & G. Partridge (Eds.), Enzymes in farm animal nutrition (2nd ed., pp. 12-53). CABI Publishing. https://doi.org/10.1079/9781845936747.0012

- Petry, A., Huntley, N., Bedford, M., Zijlstra, R. T., & Patience, J. (2020). Supplementing xylanase increased the digestibility of non-starch polysaccharides, particularly arabinoxylan, in diets high in insoluble corn fiber fed to swine with a 36-d dietary adaptation period. Journal of Animal Science, 98(52-52).

- Petry, A. L., & Patience, J. F. (2020). Xylanase supplementation in corn-based swine diets: a review with emphasis on potential mechanisms of action. Journal of Animal Science, 98(11), skaa318. https://doi.org/10.1093/jas/skaa318

- Tiwari, U., Singh, A., & Jha, R. (2019). Fermentation characteristics of resistant starch, arabinoxylan, and β-glucan and their effects on the gut microbial ecology of pigs: A review. Animal Nutrition, 5, 217-226.

- United States Department of Agriculture (USDA). (2017). Biofuel Annual. Economic Research Service. https://www.fas.usda.gov/commodities/biofuels

- Wenk, C. (2001). The role of dietary fibre in the digestive physiology of the pig. Animal Feed Science and Technology, 90, 21-33.

- Woyengo, T. A., Beltranena, E., & Zijlstra, R. T. (2014). Nonruminant nutrition symposium: controlling feed cost by including alternative ingredients into pig diets: a review. Journal of Animal Science, 92(4), 1293-1305.

- Zier-Rush, C. E., Groom, C., Tillman, M., Remus, J., & Boyd, R. D. (2016). The feed enzyme xylanase improves finish pig viability and carcass feed efficiency. Journal of Animal Science, 94(suppl_2), 115. https://doi.org/10.2527/msasas2016-244